Switch heating system KOMKON NST-20 is designed to get track switches rid of ice and snow in the cold season. The basic principle of operation of the electric heating system is the effect of heat from thermal elements on snow and ice accumulated between the tongue and the frame rail.

In the switch heating system, 2 to 4 heaters are used, each of them has a rated power up to 1000 Wt. It is possible to distance the control cabinet from the switch in up to 50 m. The length of the heater in such a system can be from 1.5 to 3.5 m. The heating automatically switches on in the temperature range from – 40°C to + 5°C.

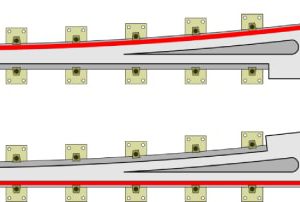

Heaters are mounted on the outer side of the track switches. The system controls the intensity of heating, taking into account data from air temperature sensors and from heaters, by turning the heating on or off. The heating power, if necessary, can vary from 0% to 100% in the temperature range from – 40°C to + 5°C.

A distinctive feature of this system is flexibility and the ability to usage on the various types of turnouts. Using of an automatic system significantly saves energy.

The advantages of switches’ electric heating KOMKON NST-20:

- Increased efficiency due to the tight fit of the heaters directly to the body of switches (minimizes heat loss);

- Electrical safety and resistance to the negative effects of circulating currents (guaranteed by galvanic isolation between the heating elements and the power source of the contact network, as well as using a safe voltage of 20V to power electric heaters);

- System tolerance to vibration and other mechanical impacts;

- Resistance to temperature changes, atmospheric precipitation and aggressive environments (provided by the use of corrosion-proof materials);

- High level of cost effectiveness.

The design solutions used guarantee the reliability and safety of the electric heating system. Furthermore, it does not matter in what conditions the operation of switches occurs. The heating elements are housed in robust galvanized steel cases and are completely sealed.

The system consists of:

- control cabinet;

- a set of heaters;

- fasteners;

- heat conducting paste;

- temperature sensors;

- set of documents.